Discover our success stories for your industry!

All Industries

Food & Beverage

Automation & Machinery

Transport & Energy

Consumer Goods & Packaging

Luxury & Cosmetics

Pharma & Health

Automotive

Chemical & Steel

Large-scale distribution & Retail

All Solutions

Industrial Vision

Industrial Intelligence

Packaging & Consumer Goods

Industrial Vision

Quality control of heat-sealed packaging

Problem

When it comes to heat-sealed flexible packaging, the speed of the line does not allow for effective visual control of quality by operators. This issue is extremely relevant since the breakage of a single package can cause the entire batch of finished packaged product to be returned.

Solution

AISent has developed an optimized vision system to identify and classify all possible dimensional and quality defects of the packaging directly on the line. A single system integrates the ability to control different types of bags, even if they are made of different and reflective materials. AISent's solution, in addition to guaranteeing quality control, keeps the history of defects updated to facilitate and validate improvements to the process.

Chemical & Steel

Industrial Vision

Robotic system for oil rig

Problem

Oil rig operations involve risky tasks that are often done manually by technicians. Critical operations, such as the integration of the sludge pumping system, take place under extreme conditions, but are vital to the safety of the facility.

Solution

By combining Computer Vision and Robot Guidance, AISent has automated the connection of the sludge pumping system. The cameras locate the anchor point and guide an anthropomorphic robot in the docking operation. To ensure the reliability of the system, it was necessary to develop an ultra-robust vision model, which is resistant to all environmental conditions. AISent's solution allows you to perform critical tasks remotely, ensuring the safety of operators and the facility.

Pharma & Health

Industrial Vision

Physiotherapy 4.0

Problem

A healthtech company has developed a system to guide physiotherapy remotely. Current 2D joints tracking systems, however, are not accurate enough to achieve quality physiotherapy. Without accurate detection in 3 dimensions, the system developed by the customer is not able to provide adequate suggestions to the patient.

Solution

To solve the problem, a 3-dimensional joints detection algorithm was developed and trained on more than 600,000 images. Using data from a camera, joints and their movements in space are precisely identified and tracked. AISent's algorithm has drastically improved the client's system, which is now able to accurately track complex, multidimensional joint movements to provide personalized instructions to patients.

Food & Beverage

Industrial Intelligence

Optimisation of energy consumption

Problem

In the brewing process, large quantities of gases are used intermittently for the production of steam. The heating system, operating on demand according to demand, often forces the boilers to work in conditions of suboptimal efficiency.

Solution

AISent has developed an intelligent system that predicts the consumption of the system thanks to a reinforcement learning algorithm and manages the boilers autonomously. By predicting fuel consumption in advance, it is possible to have optimal warm-up times through the autonomous adjustment of set-points. The solution developed by AISent makes it possible to reduce stress on boilers and reduce consumption and CO2 emissions.

Automation & Machinery

Industrial Intelligence

Predictive Maintenance for Marble Cutting

Problem

Planning maintenance is an activity that allows you to avoid breakdowns, malfunctions and production interruptions. A manufacturer of marble cutting machines wonders when is the optimal time to perform maintenance and prevent diamond wire breakage caused by wear and tear.

Solution

AISent has developed a Predictive Maintenance system that uses AI to analyze process settings, data from on-machine sensors, and environmental parameters, in order to predict the wear and tear of components. The system helps preserve industrial assets, avoid sudden production interruptions, and optimize maintenance budget management.

Consumer Goods & Packaging

Industrial Vision

Robot Guidance for Water Bottle Manufacturer

Problem

In the manufacturing industry, workers still perform simple and repetitive tasks. The incorrect manual insertion of a component into plastic processing machines causes slowdowns in the production cycle and inefficiencies for a water bottle manufacturer. In addition, during the machine loading phase, the operator is exposed to mechanical risks and thermal stress. The complexity of the piece and its correct positioning does not allow the operation to be automated with the techniques traditionally employed.

Solution

AISent has developed and integrated a solution to automate these tasks. A computer vision system has been trained to recognize the components and their orientation. An anthropomorphic robot uses this information to pick up and load the machinery in the correct way, reducing cycle time and eliminating risks for operators.

Luxury & Cosmetics

Industrial Vision

Quality Inspection in Luxury

Problem

A major luxury goods producer demands the total absence of geometric defects or surface finish imperfections, which would compromise the brand's reputation. Inspections carried out by hand by trained personnel, in addition to being costly, do not guarantee absolute repeatability. On the other hand, traditional machine vision techniques do not allow the detection of defects on products with complex geometry and very heterogeneous surface finishes.

Solution

AISent has developed Minosse, an autonomous quality control laboratory equipped with an anthropomorphic arm that guides several cameras for image acquisition on all surfaces of the product. The images were passed to a large set of Fault Detection and Anomaly Detection algorithms for the identification and classification of defects.

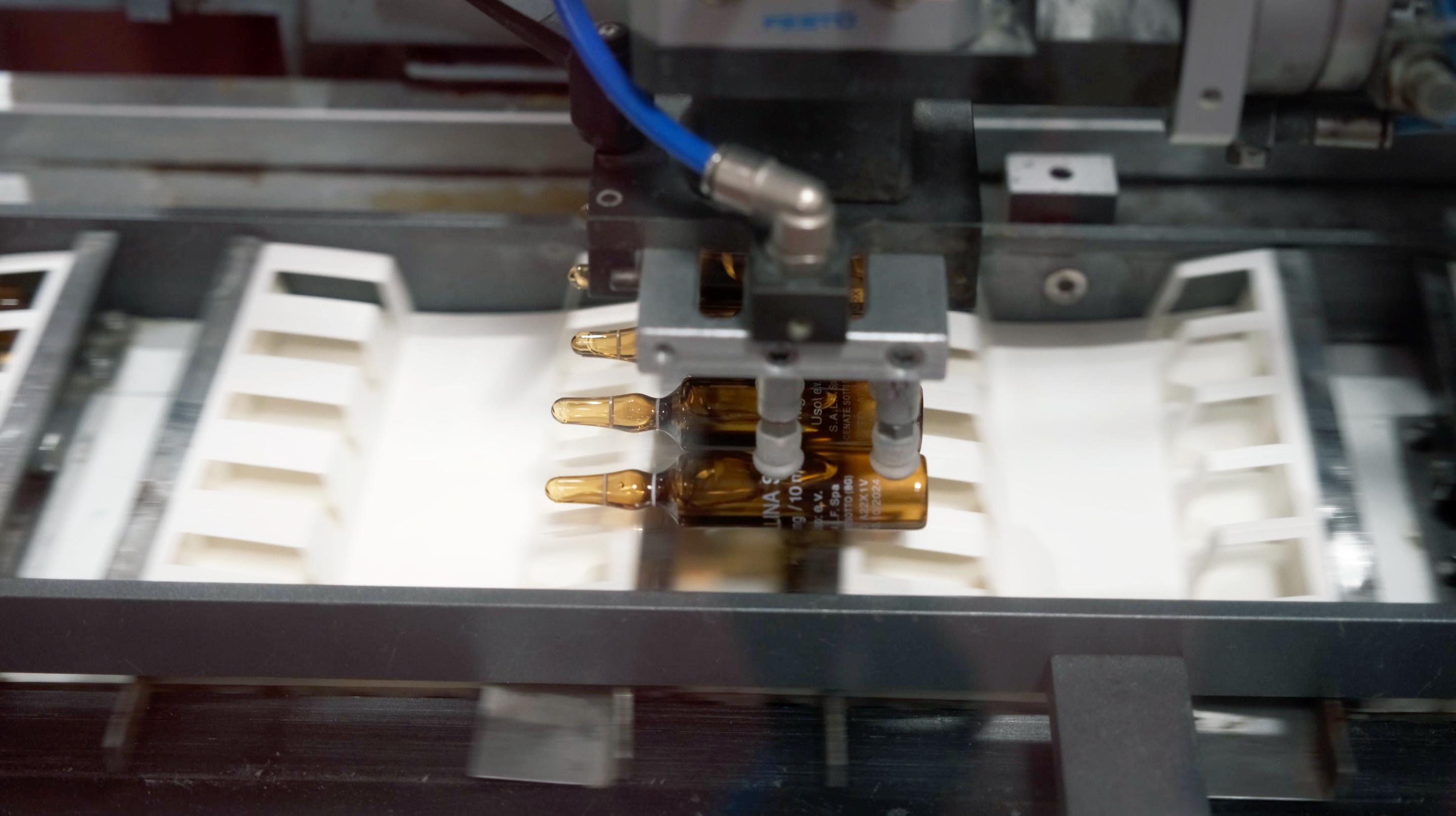

Pharma & Health

Industrial Vision

Pharmaceutical vial control

Problem

A pharmaceutical company that packages glass vials of injectable products must ensure the absolute correct composition of the multi-ampoule packs. The vials are coded with colored rings printed on the body. Colors have variability due to parameters under the control of different vial suppliers, and color rendering is influenced by the color of the vial itself. The continuous introduction of new product variants also requires easy training of the system to recognize new color combinations by the customer's staff. Given the value of the product, a false positive deviation of less than 0.1% is also required.

Solution

With a single in-line vision system, the customer recognizes all combinations of ring counts, ring colors and vial colors. The system is robust to the variability of the position of the rings. Since the introduction of the system, new ring and ampoule colours have already been introduced without difficulty. The level of false positives is below 0.05%. The system automatically generates and stores the documentation required by quality assurance on the customer's systems.

Automotive

Industrial Vision

Automatic Inspection Station for Quality Control

Problem

Quality control in the automotive industry presents challenges and issues due to the human component. Ineffective tracking and minimal distraction compromise the quality of the vehicle and lead to delays in the assembly phase. A customer in the luxury sports car industry asked AISent to improve the system for identifying and tracking cosmetic defects on sheet metal, down to the smallest and most difficult to detect.

Solution

The proposed solution is an intelligent automatic inspection station that operates during the assembly process. This collaborative solution is designed to be easily reconfigurable, either by adding inspection points or expanding case studies to new models through an algorithm training phase. In this way, it is possible to automate quality control and free the result of inspections from the presence of highly trained personnel, allowing you to guarantee world-class quality consistently over time.

Pharma & Health

Industrial Intelligence

Blood Oxygenation System

Problem

Artificial intelligence can also make its contribution to the life sciences. A biomedical device manufacturer wants to build a system to estimate blood oxygenation status (pO2) for extracorporeal circulation applications.

Solution

AISent has designed an artificial intelligence algorithm that estimates the pO2 level of the blood, at the current temperature and at 37°C, by observing the fluorescence of the liquid in response to a light pulse. The system is able to estimate the pO2 level, with error within the limits imposed by biomedical devices, regardless of the blood temperature, the probe and the light spot used.

GDO & Retail

Industrial Intelligence

Fresh demand forecast

Problem

In the world of large-scale distribution, one problem plagues many companies: demand forecasts for fresh produce are inaccurate. A major player in distribution suffers a major economic and environmental impact on a daily basis due to forecast errors.

Solution

AISent has developed a data intelligence system that combines internal and external historical data to obtain accurate forecasts. The forecasts, divided by product category, are integrated into a decision support system that also takes into account prices to make optimal procurement decisions.

Automotive

Industrial Vision

Robot guide for electric car charging

Problem

Managing the electric refueling of a vehicle may not be accessible to those who are unable to physically handle the charging process due to age or a disability. In addition, inclement weather conditions can make the operation inconvenient for anyone.

Solution

For a customer in the electric vehicle charging sector, AISent has developed a robot vision and guidance system that recognizes the charging plug, its angle and the docking path, allowing energy replenishment without the intervention of the customer or an operator.

Transports & Energy

Industrial Vision

Forecasting waiting times and managing passenger flows

Problem

Queues, checks and waiting times at the airport: these are the concerns that passengers have, before leaving for a plane trip. The difference between a positive experience and a nightmarish trip is the hours wasted in the check-in and security queues, instead of being able to take advantage of shops and restaurants.

Solution

AISent has perfected and put into production at some important Italian airports tracking algorithms that estimate the number of passengers present in certain spaces, study their behavior, predict waiting times and optimize flow management. All this happens thanks to the images of the surveillance cameras already present at the airport.

Consumer Goods & Packaging

Industrial Intelligence

Intelligent Troubleshooting for the Plastics Industry

Problem

When defects or malfunctions occur in the plastic extrusion and blow molding process, problem identification and resolution may not be immediate, especially in the absence of experienced technicians. Often, out of necessity, we proceed by trial and error, modifying one or more parameters according to individual sensitivity and experience.

Solution

AISent worked with a machine builder and a converter to gather knowledge from five experts and to create the starting model of the diagnostic and troubleshooting tool. The model preserves the knowledge of expert technologists, supports the troubleshooting process of operators and facilitates communication between operators and remote service. This solution guides you step-by-step towards solving the problem with a user-friendly interface. The same tool is used to accelerate the training of new technologists and operators.

GDO & Retail

Industrial Vision

Effective and safe palletizing with AI

Problem

With customers and suppliers requiring fruit crates of varying sizes, the automated palletizing system proves inadequate. This system, designed to work with standard cassettes, fails to efficiently recognize and organize cassettes of different sizes. This can lead to battery stability issues, product damage, and delays in preparing loads.

Solution

AISent has developed a vision system capable of recognising different types of packaging. Information on the type of packaging is communicated to the palletizing system already in use, ensuring optimal pallet construction. AISent's solution makes it possible to eliminate battery stability problems, thus avoiding accidental damage.

Luxury & Cosmetics

Industrial Intelligence

Raw Material Purchasing Decision Support System

Problem

With a wide variety of raw materials whose prices can be affected by exchange rates and other ever-changing factors, the purchasing department of a cosmetics company is faced with complex challenges. The company must balance the goal of avoiding material shortages with that of minimizing the financial cost. In addition, it is crucial to manage the quantities purchased from each supplier to achieve significant discounts.

Solution

AISent has implemented automated computational operations that were previously performed manually. In addition, with predictive models, it has created a Decision Support System that orients the purchasing process by taking into account the forecasting of internal and external variables. AISent's solution freed the purchasing department from repetitive tasks. This solution allows you to spend more time on strategic decisions, which are driven by data.

GDO & Retail

Industrial Intelligence

Estimation of customers' overdrafts and overdrafts

Problem

For a supplier, the estimation of the customer's reliability and the consequent quantification of the credit line to be granted is an important operation, since the accuracy in this assessment has a direct impact on financial risk management. Added to this are the requests for the granting of extra-credit facilities. The workload, which is currently managed by a single operator, can result in a non-in-depth assessment that ultimately results in excessive financial exposure of the company.

Solution

AISent has developed a Decision Support System that integrates data from different macro-areas, from financial to social and environmental, to estimate the general reliability of a customer and, consequently, refine the initial quantification and revaluation of the credit line. This system also suggests a punctual assessment of the possible granting of the extra-credit limit, justified on the basis of the critical issues that emerge from the estimation of the macro-area data.

GDO & Retail

Industrial Intelligence

RPA for master data management

Problem

A company, which deals with the management of personal data databases, must coordinate the resolution of out-of-stock cases, reported by customers, for which support chats are opened. Manually entering each additional code into the database, as well as generating the invoice and credit note, is time-consuming. It is therefore necessary to implement them automatically in order to streamline manual processes.

Solution

AISent has developed an algorithm that, given the chats of closed tickets, is able to recognize the case history of the solution and, consequently, the operation to be implemented on the database that is automatically executed. This allows operators to focus on the more elaborate problems, relieving them of the need to deal with the simplest ones.