In the absence of real data, we are able to create synthetic databases to train and test models, simulating complex scenarios.

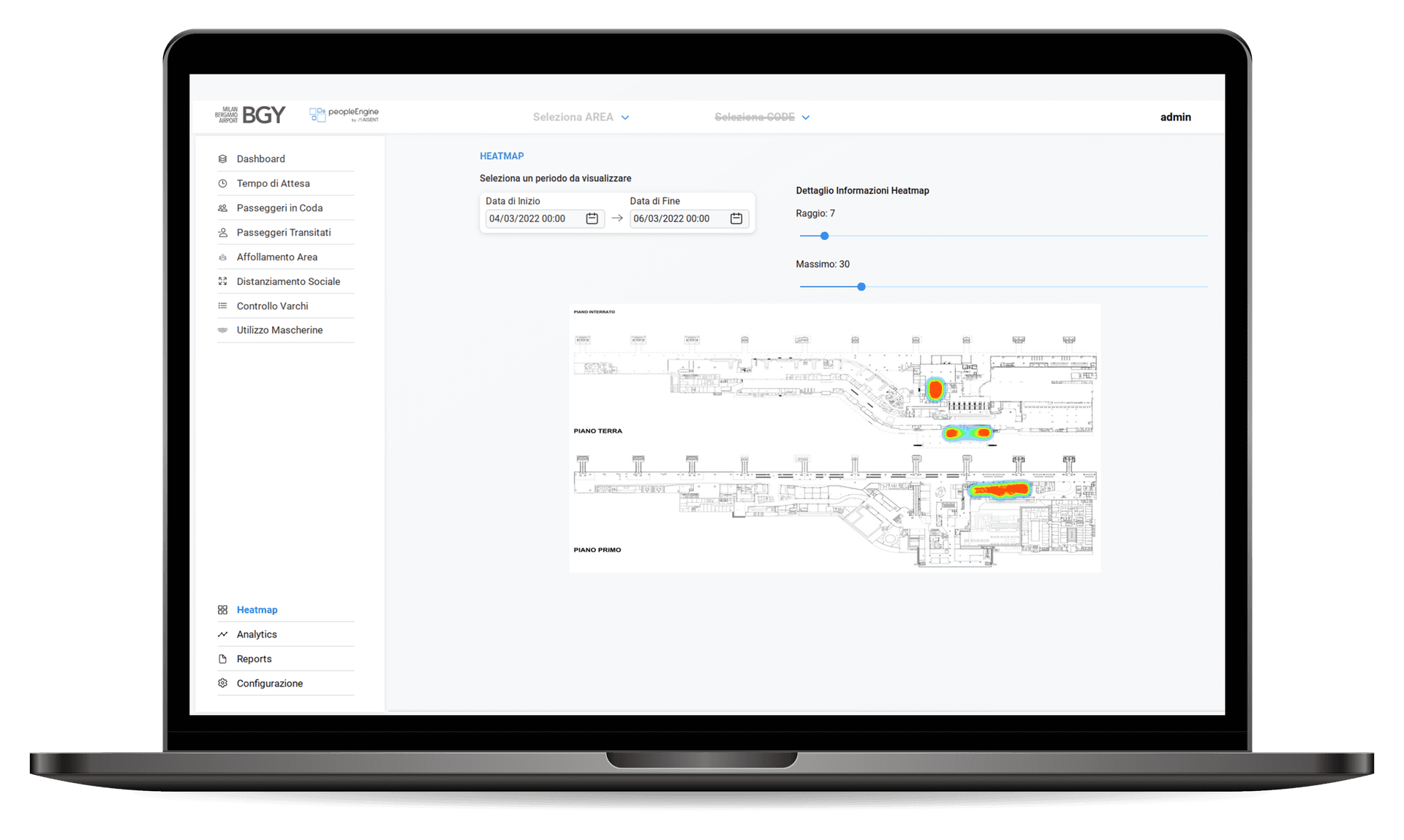

Chandra and peopleEngine are our ready-to-use image analytics platforms to optimize development time and scalability of our solutions.

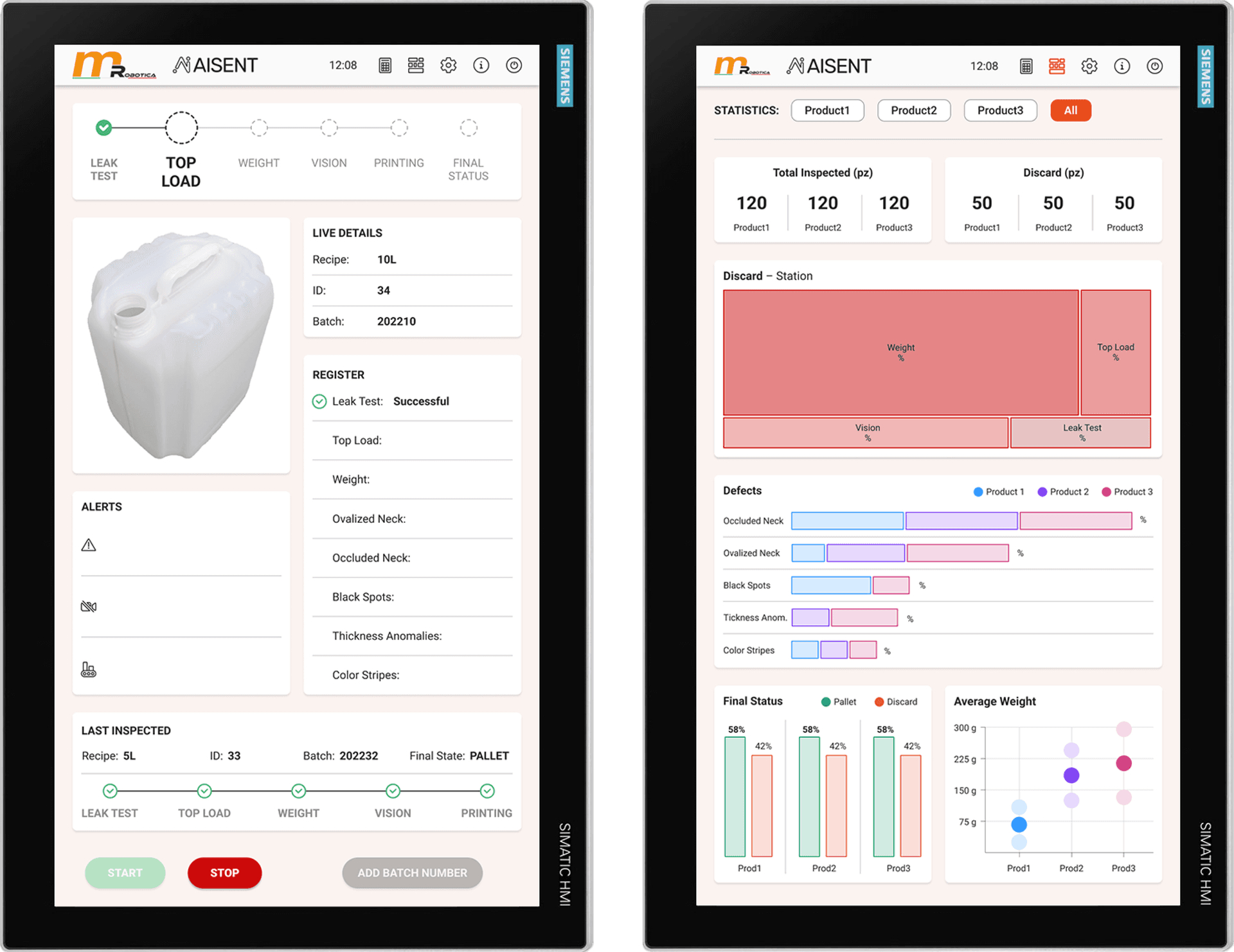

Inspection, control and tracking

Through visual inspection, our systems reveal flaws and anomalies, even those that are difficult to see, with the same skill as an experienced operator. Our solutions are able to monitor thousands of products per hour, allowing quality control of the entire production, even in real time.

Robot Guidance

The combination of artificial intelligence and cameras enables robots to perform tasks autonomously, accurately, and efficiently in complex production environments. Guided robots operate safely and collaboratively with operators, ensuring consistent quality.

Customized solutions of Industrial Vision

We provide customized solutions that fit the particular needs of our customers. Based on the analysis of your problem and requirements, tailor-made solutions are developed.

Our Industrial Vision Laboratories

Through our Industrial Vision laboratories, we test the technical feasibility of your needs. After receiving the object to be examined, our engineers conduct a series of tests with different camera configurations. In just a few days, you will receive a preview of the technical feasibility and an estimate of the performance that our solution is able to offer.

Intelligent system for the analysis of people flows in shopping malls, airports, train stations, museums and theme parks. This software provides a dashboard with statistics and heatmaps that allows you to improve asset management, security, and the quality of customer experience. peopleEngine can also be applied easily using existing cameras, that avoids additional costs.

Chandra is the software platform that underpins our Industrial Vision solutions. Chandra interfaces with the customer's hardware and software and enables the integration of AI models. In addition, it automatically historicizes images and production data, making them available for more in-depth analysis. To ensure greater precision, the models are tailor-made for each customer, while the ready-to-use configuration allows you to create your own recipes quickly and independently.